X Close Panel

Interested in learning more about Bondhus? Contact us and we'll get back to you with the information you're looking for.

Bondhus Corporation

1400 E. Broadway

P.O. Box 660

Monticello, Minnesota 55362

Phone: 800-328-8310

Hours: 7:00 AM to 5:00 PM CST

Technical Library

Hex and TORX® Fasteners

The fasteners used with hex tools are available in an incredibly wide range of sizes and strengths, and with features unique to the various types. Hex fasteners are available for nearly any assembly project where critical factors will not permit the use of lower quality alternative fasteners.

Common Screw Types:

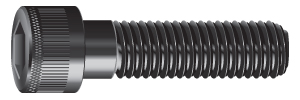

Socket Head Cap Screw

Uses: Applications where maximum strength is required. Used as protruding or counter bored.

Variations: A range of choices available for special use applications:

- High temperature

- Corrosive environments

- Maximum tensile strength critical

- Cleanliness required

Low Head Socket Head Cap Screw

Uses: Applications where parts are not thick enough to be counterbored or clearance is too limited to use full height cap screw.

Socket Set Screw

Uses Fastening parts on a shaft – pulleys, gears, collars, etc.

Variations: Options include:

- High-temperature applications

- Corrosive environments

- The range of points available to accommodate: shafts of varying hardness; parts needing frequent adjustment or removal; applications where positive locking critical.

Button Head Screw

Uses: Applications with low limited clearance: parts are not thick enough to be counterbored; loading capacity is not critical.

Shoulder Screw

Uses: Applications where the shoulder screw can actually replace more expensive parts such as trunnion mountings, shafts, or guides.

Flat Head Screw

Uses: Applications where head needs to be flush with surface

Advantages of Socket Head Screws:

Strength: An assembly with three socket head cap screws has more strength than one with five equivalent hex head screws.

Strength: An assembly with three socket head cap screws has more strength than one with five equivalent hex head screws.

Savings: Using fewer screws means labor savings associated with drilling fewer holes and installing fewer screws.

Tensile, yield, and shear strength: An assembly done with a cap screw has over 50% more tensile strength, 100% better yield strength, and over 30% more shear strength.

Clearance: Socket head cap screws have no side clearance restrictions associated with the sockets and wrenches used with hex head screws. As a result, they can be placed closer together, and used in applications where associated side clearance would make hex head screws impractical. When overhead clearance is an issue, or a flush profile is necessary, the low head and flat head versions are a good solution.