Torque Comparison

Maximum torque of Bondhus tools and several of our competitors.

Learn More

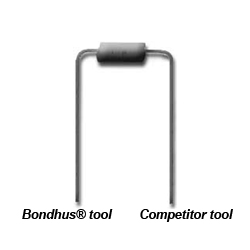

T-Handle comparisons

Compare the breaking point of Bondhus, Eklind, and Allen T-Handles.

Learn More

Project number 3018 99-07600

Date: March 3, 1999

MAXIM TECHNOLOGIES, INC.

662 Cromwell Avenue

St. Paul, Minnesota 55114

Project: Torque Testing

Client Purchase Order Number: Verbal

Prepared By: Scott W. Britzius Project Engineer/Experimental Mechanics Mechanical Engineering Department

Reviewed By: Richard S. Alberg Manager Mechanical Engineering Department

Phone: (651) 659-7307

"An Affirmative Action, Equal Opportunity Employer"

The test results contained in this report pertain only to the samples submitted for testing and not necessarily to all similar products.

Comparison Performance Torque Testing

INTRODUCTION:

This report presents the results of comparison performance tests conducted on T-Handle Hex wrenches produced by three manufacturers. The testing was requested on March 3, 1999 by Mr Mike Blackston of the Bondhus Corporation.

The scope of work was limited to purchasing the two competitor brand of wrenches directly from an industrial distributor. Determining the torque required to fracture (break) the three manufacturers wrenches and to provide a report of the results.

SUMMARY OF RESULTS:

Average Torque to Fracture (break) Off Wrench, in-lb

| Wrench Size |

Bondhus |

Eklind |

Allen |

| 1/4 inch |

869 |

781 |

756 |

| 7/32 inch |

625 |

513 |

507 |

| 3/16 inch |

387 |

336 |

319 |

| 5/32 inch |

225 |

188 |

187 |

| 9/64 inch |

158 |

135 |

131 |

| 1/8 inch |

115 |

84 |

98 |

| 7/32 inch |

77 |

59 |

63 |

| 3/32 inch |

46 |

37 |

38 |

SAMPLE IDENTIFICATION:

T-Handle style Hex Wrenches. The Bondhus® wrenches were submitted on 3-4-99. Maxim Technologies purchased from MSC Industrial Supply Company, five (5) wrench sets of: ALLEN -Cushion Grip P/N 75043513 and EKLIND - Wire Form P/N 05044516 under our Purchase Order number 52205 dated 3-10-99. The wrenches were received at our facility via UPS on 3-12-99. The wrench sizes, shank length and T-handle dimensions are listed on the following page.

Wrench Dimensions, inches

Shank Length - Handle Width / Diameter

| Wrench Size |

Bondhus |

Eklind |

Allen |

| 1/4 inch |

5.8 - 4.1/0.7

(P/N 13312) |

6.0 - 4.1/0.9 |

5.4 - 5.0/0.65 |

| 7/32 inch |

5.3 - 4.1/0.7

(P/N 13311) |

6.0 - 4.0/0.8 |

5.4 - 4.2/0.65 |

| 3/16 inch |

4.8 - 4.1/0.65

(P/N 13310) |

6.0 - 4.0/0.7 |

5.4 - 4.2/0.65 |

| 5/32 inch |

4.6 - 3.1/0.5

(P/N 13309) |

6.0 - 3.1/0.65 |

5.6 - 3.1/0.45 |

| 9/64 inch |

4.3 - 3.1/0.7

(P/N 13308) |

6.0 - 3.1/0.6 |

5.6 - 3.1/0.45 |

| 1/8 inch |

4.0 - 3.1/0.5

(P/N 13307) |

6.0 - 3.1/0.6 |

5.6 - 3.1/0.45 |

| 7/32 inch |

3.8 - 3.1/0.5

(P/N 13306) |

6.0 - 3.0/0.5 |

5.6 - 2.4/0.45 |

| 3/32 inch |

3.5 - 3.1/0.5

(P/N 13305) |

6.0 - 3.0/0.5 |

5.6 - 2.4/0.40 |

TEST METHODS:

The size, shank length, handle width and diameter of the wrenches were documented. The torque testing was conducted by placing the shank of the wrench into the matching size of a hex driver socket attached to a 2,000 in-lb torque transducer. The handle of the wrenches were rotated in the clockwise direction using a fixture (see drawing on page 6) designed to contact the handle with two (2), 3/8" diameters on opposite sides, at the span of; 2" for the 5/23" - 3/32" wrenches and 2-1/2" for the 1/4" - 3/16" wrenches. The wrenches were torqued until either the shank fractured (broke), spun loose in the handle or handle deformation caused loss of contact with the torque fixture. The indicated maximum peak torque and mode of break were documented for the wrenches.

TEST EQUIPMENT:

Lebow 2000.0 in-lb torque transducer, MTI# MM 120-002, calibrated traceable to the NIST on 2-3-98 due 2-3-00.

TEST DATA:

Torque to Break Wrench, in-lb. Mode of Failure (see below)

1/4" Wrench size

| Trial # |

Bondhus |

Eklind |

Allen |

| 1 |

857 |

832 |

751 |

| 2 |

840 |

759 |

747 |

| 3 |

880 |

777 |

750 |

| 4 |

881 |

681 |

770 |

| 5 |

888 |

855 |

763 |

| Average |

869 |

781 |

756 |

7/32" Wrench size

| 1 |

624 |

521 |

506 |

| 2 |

598 |

518 |

506 |

| 3 |

631 |

520 |

511 |

| 4 |

630 |

504 |

511 |

| 5 |

641 |

503 |

503 |

| Average |

625 |

513 |

507 |

3/16" Wrench size

| 1 |

400 |

333 |

330 |

| 2 |

390 |

324 |

329 |

| 3 |

381 |

343 |

314 |

| 4 |

383 |

341 |

311 |

| 5 |

380 |

339 |

311 |

| Average |

387 |

336 |

319 |

5/32" Wrench size

| 1 |

221 |

190 |

193 |

| 2 |

224 |

188 |

184 |

| 3 |

234 |

189 |

189 |

| 4 |

223 |

183 |

186 |

| 5 |

221 |

188 |

184 |

| Average |

225 |

188 |

187 |

Mode of Failure:

Bondhus and Allen - the shank of the wrenches twisted into a spiral and then fractured.

Eklind - the wire handles deformed resulting in loss of contact with the torque fixture. Twisting and bending of the shanks also occurred during torquing, but no shank fractures occurred.

TEST DATA: (cont')

Torque to Break Wrench, in-lb.Mode of Failure (see below)

9/64" Wrench size

| Trial # |

Bondhus |

Eklind |

Allen |

| 1 |

160 |

137 |

131 |

| 2 |

152 |

136 |

130 |

| 3 |

161 |

137 |

131 |

| 4 |

159 |

135 |

131 |

| 5 |

158 |

131 |

130 |

| Average |

158 |

135 |

131 |

1/8" Wrench size

| 1 |

105 |

89 |

97 |

| 2 |

114 |

85 |

101 |

| 3 |

118 |

82 |

94 |

| 4 |

114 |

82 |

99 |

| 5 |

119 |

82 |

101 |

| Average |

115 |

84 |

98 |

7/64" Wrench size

| 1 |

78 |

62 |

63 |

| 2 |

77 |

55 |

60 |

| 3 |

77 |

60 |

63 |

| 4 |

76 |

60 |

64 |

| 5 |

79 |

60 |

62 |

| Average |

77 |

59 |

63 |

3/32" Wrench size

| 1 |

46 |

38 |

40 |

| 2 |

45 |

37 |

37 |

| 3 |

46 |

37 |

37 |

| 4 |

45 |

36 |

38 |

| 5 |

46 |

37 |

37 |

| Average |

46 |

37 |

38 |

Mode of Failure:

Bondhus and Allen - the shank of the wrenches twisted into a spiral and then fractured.

Eklind - the wire handles deformed resulting in loss of contact with the torque fixture. Twisting and bending of the shanks also occurred during torquing, but no shank fractures occurred.

REMARKS:

The wrenches will be retained for thirty days then discarded unless otherwise notified.

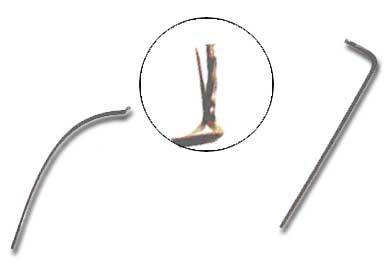

Hex Key Comparisons

The results of an independent study showing the breaking point of Bondhus, Eklind, and Allen L-Wrenches.

Learn More

Torque Comparison

Project number 3018 99-05234

Date: January 29, 1999

MAXIM TECHNOLOGIES, INC.

662 Cromwell Avenue

St. Paul, Minnesota 55114

Project: Torque Testing

Client Purchase Order Number: Verbal

Prepared By: Scott W. Britzius Project Engineer/Experimental Mechanics Mechanical Engineering Department

Reviewed By: Richard S. Alberg Manager Mechanical Engineering Department

Phone: (651) 659-7307

"An Affirmative Action, Equal Opportunity Employer"

The test results contained in this report pertain only to the samples submitted for testing and not necessarily to all similar products.

Comparison Performance Testing

INTRODUCTION:

This report presents the results of comparison performance tests conducted on eight specified sizes of hex wrenches produced by three manufacturers. The testing was requested on January 4, 1999 by Mr. Mike Blackston of the Bondhus Corporation.

The scope of work was limited to purchasing the hex wrenches directly from an industrial distributor, determining the torque to fracture (twist off) the wrenches and providing a report of the results. The testing was completed on January 27, 1998.

SUMMARY OF RESULTS:

Average Torque to Fracture (break) Off Wrench, in-lb

MANUFACTURER

| Wrench Size |

Bondhus |

Eklind |

Allen |

| 1/16 inch |

15 |

11 |

11 |

| 5/32 inch |

225 |

190 |

160 |

| 1/4 inch |

920 |

765 |

725 |

| 5/16 inch |

1760 |

1525 |

1390 |

| 1.5 mm |

12 |

10 |

9 |

| 4 mm |

230 |

165 |

160 |

| 6 mm |

760 |

650 |

610 |

| 8 mm |

1710 |

1540 |

1440 |

SAMPLE IDENTIFICATION

Ball End style hex wrenches purchased from MSC Industrial Supply Co. under Maxim Technologies purchase order number 51345 on 1-14-99 and shipped to our facility by UPS. Five (5) wrenches each in the size and leg lengths listed below were purchased.

SAMPLE IDENTIFICATION:

| Manufacture: |

Size |

Length |

Size |

Length |

| Bondhus |

1/16 |

1/2" x 3" |

1.5 mm |

1/2" x 3" |

| |

5/32 |

3/4" x 4" |

4 mm |

1" x 4" |

| |

1/4 |

1-1/4"x5" |

6 mm |

1-1/4"x5-1/2" |

| |

5/16 |

1-1/2" x 6" |

8 mm |

1-1/2" x 6" |

| Eklind Tool |

1/16 |

1/2" x 3" |

1.5 mm |

1/2" x 3" |

| |

5/32 |

3/4" x 4" |

4 mm |

1" x 4" |

| |

1/4 |

1-1/4"x 5" |

6 mm |

1-1/4"x5-1/2" |

| |

5/16 |

1-1/2"x6" |

8 mm |

1-1/2"x6" |

| Allen |

1/16 |

1/2" x 3" |

1.5 mm |

1/2" x 3" |

| |

5/32 |

3/4" x 4" |

4 mm |

1" x 4" |

| |

1/4 |

1-1/4" x 5" |

6 mm |

1-1/4"x5-1/2" |

| |

5/16 |

1-1/2" x 6" |

8 mm |

1-1/2" x 6" |

TEST METHODS:

The size, leg lengths and end styles of the wrenches purchased were documented. The torque testing was conducted by placing the shorter leg of the wrench 3/16" into the matching size of a hex driver socket. The hex socket was attached to a 2,000.0 in-lb torque transducer. To obtain the required leverage to stress the wrench, an extension arm (pipe) was placed over the longer leg to terminating 1 inch from 90° bend. The wrenches were then torqued clockwise until the wrench fractured (broke) off. The indicated maximum peak torque and location of break were documented for each wrench.

TEST EQUIPMENT:

Lebow 2K in-lb torque transducer, MTI# MM 120-002, calibrated traceable to the NIST on 2-3-98 due 2-3-00.

TEST DATA:

Torque to fracture (break) off wrench, in-lb.

1/16" Wrench size

| Trial # |

Bondhus |

Eklind |

Allen |

| 1 |

16 |

11 |

10 |

| 2 |

15 |

11 |

10 |

| 3 |

16 |

12 |

12 |

| 4 |

15 |

10 |

11 |

| 5 |

15 |

11 |

11 |

| Average |

15 |

11 |

11 |

5/32" Wrench size

| 1 |

239 |

195 |

175 |

| 2 |

200 |

189 |

157 |

| 3 |

233 |

192 |

150 |

| 4 |

243 |

192 |

138 |

| 5 |

220 |

190 |

170 |

| Average |

225 |

190 |

160 |

1/4"Wrench size

| 1 |

922 |

789 |

724 |

| 2 |

910 |

764 |

720 |

| 3 |

950 |

754 |

731 |

| 4 |

902 |

754 |

724 |

| 5 |

927 |

761 |

719 |

| Average |

920 |

765 |

725 |

5/16"Wrench size

| 1 |

1,789 |

1,521 |

1,371 |

| 2 |

1,764 |

1,513 |

1,430 |

| 3 |

1,778 |

1,535 |

1,403 |

| 4 |

1,735 |

1,546 |

1,371 |

| 5 |

1,740 |

1,501 |

1,382 |

| Average |

1,760 |

1,525 |

1,390 |

In all cases the wrenches broke at the start of the socket driver with permanent twisting of the shorted leg occurred prior to breaking.

TEST DATA:(cont')

Torque to fracture (break) off wrench, in-lb.

1.5 mm Wrench size

| Trial # |

Bondhus |

Eklind |

Allen |

| 1 |

11 |

10 |

9 |

| 2 |

12 |

9 |

10 |

| 3 |

12 |

11 |

10 |

| 4 |

12 |

11 |

9 |

| 5 |

13 |

10 |

9 |

| Average |

12 |

10 |

9 |

4 mm Wrench size

| 1 |

249 |

163 |

180 |

| 2 |

215 |

147 |

132 |

| 3 |

231 |

182 |

164 |

| 4 |

235 |

162 |

175 |

| 5 |

235 |

177 |

148 |

| Average |

230 |

165 |

160 |

6 mm Wrench size

| 1 |

786 |

653 |

621 |

| 2 |

750 |

642 |

584 |

| 3 |

742 |

656 |

613 |

| 4 |

758 |

640 |

607 |

| 5 |

752 |

650 |

617 |

| Average |

760 |

650 |

610 |

8 mm Wrench size

| 1 |

1,733 |

1,535 |

1,431 |

| 2 |

1,704 |

1,526 |

1,426 |

| 3 |

1,707 |

1,557 |

1,480 |

| 4 |

1,693 |

1,543 |

1,424 |

| 5 |

1,712 |

1,550 |

1,428 |

| Average |

1,710 |

1,540 |

1,440 |

In all cases the wrenches broke at the start of the socket driver with permanent twisting of the shorted leg occurred prior to breaking.

REMARKS:

The wrenches will be retained for thirty days than discarded.